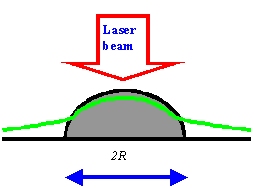

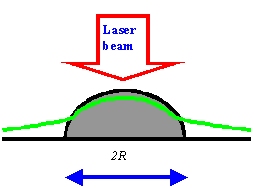

The presence of the deposit changes the temperature distribution significantly. Most interesting case is when deposit is better heat conductor than substrate: KD>>KS. In this case heat dissipates into the substrate over the area determined by the deposit and not by the laser beam. This area is significantly bigger and the resulting temperature distribution is much smaller. As deposit grow, temperature changes (decreases) further in a self-consistent way. Due to small size of the features, temperature is quasi-stationary.

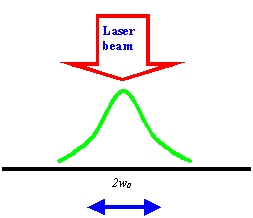

No deposit With deposit

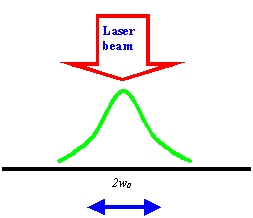

Laser direct writing is performed by scanning the laser over the substrate. It permits single step patterning (even on 3D objects). If the geometry of stripe -- height h, half width r, are known, one can determine temperature distribution. But the geometry of stripe in turns depends on the growth rate, which depends on temperature distribution. This means that these two problems -- growth and temperature distribution must be solved together. If the absorptivity of deposited material depends on temperature this may result in oscillations of height and width of the stripe.

Simulation of these oscillations requires simultaneous

solution of time dependent growth equation and three dimensional (3D) quasi-stationary

heat conduction equation in quite complicated

geometry. It was possible to reduce 3D heat equation to 2D problem

with the help of certain averaging procedure. The resulting equations were

solved by combination of fast Fourier transform (FFT) and mutli-grid technique.